You face a clear mandate in 2026. You must scale automation for speed and resilience while you grow human capital for agility and innovation. Treat it as a false trade-off. The winners pair machines that do repeatable work with people who solve new problems. Your job is to set priorities, improve ROI, and help teams adopt tools they trust. This guide shows where to automate, where to leave to humans, and how to build an operating model to support both. It centers on manufacturing leadership 2026: automation vs. human capital as a single strategy.

The 2026 Manufacturing Context: Demand, Labor, And Tech Maturity

Manufacturers in 2026 face a mix of opportunity and pressure. Demand is strong but unpredictable. Customers expect quick turnarounds, smaller production runs, and flawless quality. At the same time, the labor market remains tight. Skilled technicians and operators are harder to find and retain. Adding to the challenge, studies suggest more than 12% of U.S. jobs face a high risk of automation-related displacement, with manufacturing among the first industries to feel the effects.

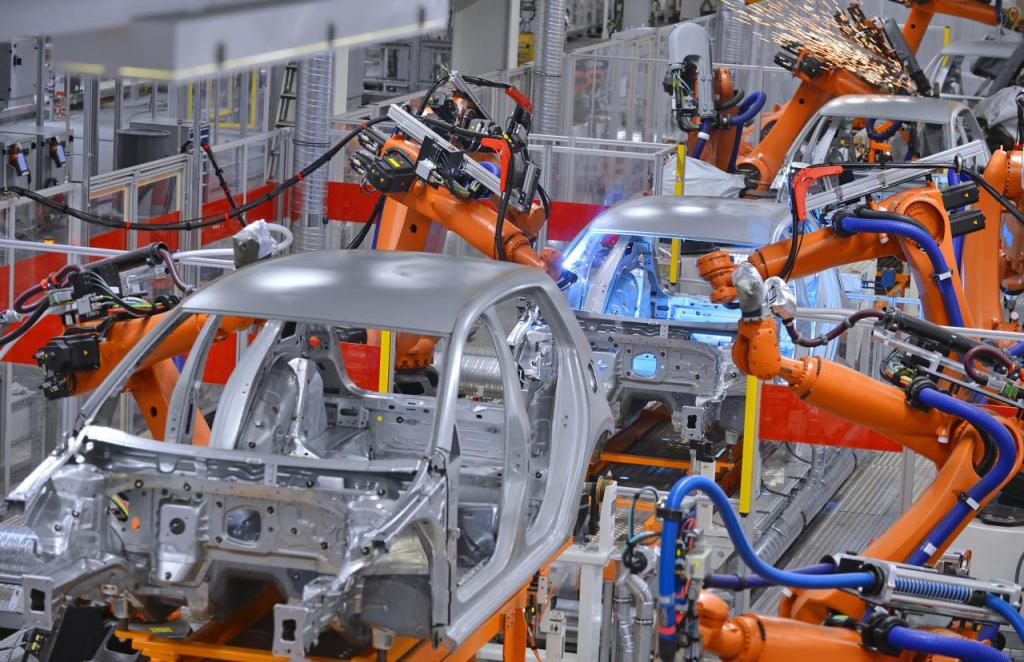

On the technology front, the tools are ready. Vision systems, cobots, IIoT, and edge AI are no longer experimental; they’re proven on real production lines. Costs have dropped, and interoperable platforms make integration far less painful than before. But technology on its own won’t create lasting advantages. Success depends on how well leaders blend advanced tools with skilled people, clear processes, and practical workflows. For many organizations, 2026 is the pivotal year to lock in that mix and scale it across plants.

A Balanced Thesis: Human-Centered Automation, Not Either/Or

The automation conversation is often framed as a trade-off, but in practice, it’s not about choosing between people and machines; it’s about designing them to work together. Human-centered automation focuses on removing hazards, reducing errors, and freeing employees to contribute in higher-value ways.

Think of it as a formula: AI + HI = ROI. Machines excel at quickly and consistently spotting patterns. People excel at judgment, handling exceptions, and adapting processes. When combined, the result is greater efficiency and resilience.

The practical playbook is straightforward:

- Automate the repeatable, data-heavy tasks.

- Elevate people for problem-solving, customer decisions, and production changes.

This approach doesn’t eliminate jobs, it transforms them. By investing in both skills and tools, manufacturers build stronger teams while strengthening performance. The payoff is quality, reliability, and responsiveness, without pushing teams to burnout.

Where To Automate Now: High-ROI, Low-Regret Use Cases

AI Vision for Quality and Traceability

Deploy AI vision to catch defects early and log evidence you can trust. Pair cameras with machine learning at the edge for fast decisions. Link results to your MES for lot-level traceability. Plants see fewer escapes, faster root cause, and tighter process windows. Start on one high-defect station. Tune labels, lighting, and reject logic. Then scale to sister lines with the same template.

Predictive Maintenance with Edge Analytics

Instrument critical assets with sensors. Stream data to an edge gateway that runs models near the machine. Detect vibration or thermal changes before failure. Push work orders to your CMMS with clear thresholds. You cut unplanned downtime and reduce spare parts guesswork. Begin with the bottleneck asset. Set a baseline, define alerts, and review weekly with operators and maintenance.

Cobots for Ergonomics and Throughput

Use collaborative robots to handle lifting, pick-and-place, and simple assembly. Cobots reduce injury risk and maintain steady cycle time across shifts. You can re-task them in hours, not weeks. Add a small vision kit and end effector swaps for flexibility. Train operators to teach waypoints. The goal is safe, stable flow, not full lights-out.

Dynamic Scheduling and Energy Optimization

Adopt AI scheduling to react to mix, material constraints, and changeovers. Combine it with energy-aware logic that shifts non-urgent loads off-peak. You improve on-time delivery and reduce costs without new hardware. Feed it real capacity, changeover times, and energy prices. Let supervisors approve final plans to maintain trust.

Where Humans Lead: Capabilities To Elevate

Problem-Solving and Exceptions

When data gets messy or processes drift, people step up. Quick huddles, shared signals, and fast decisions keep production moving and systems learning.

Continuous Improvement

Line redesign is still a human strength. With modular setups, kaizen bursts, and real-time updates, teams can cut waste and lock in gains faster than any algorithm.

Customer-Driven Customization

Special orders and short runs demand a human touch. Teams adapt steps, check details, and ensure fit and finish, while automation supports prep and checks.

Building the 2026 Operating Model: Balancing ROI, Risk, and Trust

Looking Beyond Labor Savings

ROI isn’t just about cutting labor costs. The strongest portfolios deliver gains in agility, quality, safety, and customer service. Track metrics like on-time delivery, first-pass yield, incident rates, and energy per unit. Rank initiatives by impact, ease of use, and speed to value.

From Pilot to Scale

Start small with time-boxed pilots that prove reliability, data quality, and operator acceptance. Build in safety, cybersecurity, and privacy checks from the start. When a pilot succeeds, scale with standard kits, templates, and training. Capture lessons centrally so each rollout moves faster than the last.

Smart Architecture Choices

Decide what’s strategic to own and what’s better to buy. Favor open platforms and APIs to avoid headaches from custom integration. Use edge systems for speed and cloud for scale. Keep a clear governance framework: who owns the data, who can access it, and how it’s tracked over time.

Keeping Safety and Trust First

Every automation cell should pass formal risk reviews. Validate safe zones, speeds, and guard mechanisms. Document AI limits and bias checks. Maintain audit trails for quality and safety decisions, with clear escalation paths when the system is uncertain. The standard is simple: solutions must be safe, traceable, and fair.

Turning Strategy Into Action

Manufacturing in 2026 isn’t about choosing between automation and people; it’s about pairing them to unlock agility, quality, and growth. The leaders who thrive will be those who treat automation and human capital as a single, connected strategy.

Sheer Velocity specializes in helping organizations find and develop leadership talent that balances automation with human capital. From executives who drive automation initiatives to leaders who inspire and grow skilled teams, we connect you with the right people to deliver lasting results.